PVB and EVA film

|

|

G |

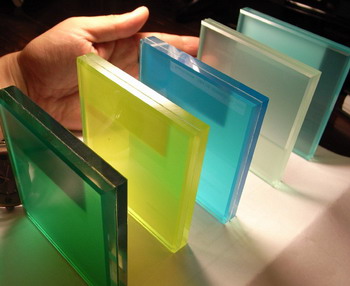

PVB, EVA film is used to be an interlayer film sandwiched in between two pieces of glass.

It is distinctive in giving versatile design and meanwhile, safety properties

|

|

G |

PVB (Polyvinyl buytral) film has been widely used in last 30 years as interlayer in laminated glass for its durability, versatility and ability to protect people and property.

However, the strong affinity to moisture makes PVB film difficult to be stored and processed without particular concerns on humidity.

Moreover, large investment and high power consumption with the glass processing system has become an entry barrier for people who are interested in this

business.

|

Therefore, one step EVA interlayer glass lamination process has emerged as substitution and drawn more and more attention.

|

G |

EVA (Ethylene Vinyl Acetate ) also know as EN film is a high adhesive film. It is made of polymer resins of ethylene vinyl acetate. It possesses the characteristics of high tensile strength, excellent transparency,

outstanding cohesion, good temperature withstanding, humidity durability and long-term reliability. One of the major applications of EVA film is as interlayer for making laminated safety and decorative glass.

It bonds well with variety of materials (PET film, polycarbonate sheet, rice paper, leaves, etc.).

|

|

G |

Glass laminated with EVA interlayer can provide great safety and security features:

• Effective for reducing shattered glass pieces shattering when broken. Also improves penetration resistance

• Effective for prevention of the injury or coming down of the glass caused from a collision.

• Able to reduce the damage levels from natural disasters such as earthquakes, hurricanes and explosions

• When incorporated with PET film, it shows significant improvement in anti-burglary properties

However, you must use EVA film if you are going to make art decoration laminated safety glass with rice paper, photos, wire, metal sheet, etc.

because PVB lamination is two steps process and not capable of fulfil such a task.

|

It is important to think about flexibility also:

Example: The lamination of lighting LED embedded films between glass may be done with PVB as well as with EVA.

However, PVB is laminated mainly in big autoclaves. Consequently 2 - 20 tons of glass are laminated together with standard lamination parameters.

In the case of smaller EVA Oven technique, the laminating unit may use optimised parameters without disturbing the standard lamination.

ผลิตภัณฑ์กระจกตกแต่งอื่นๆ ของ บริษัท ดีดีเอสวี คอนเซ็ปท์ จำกัด